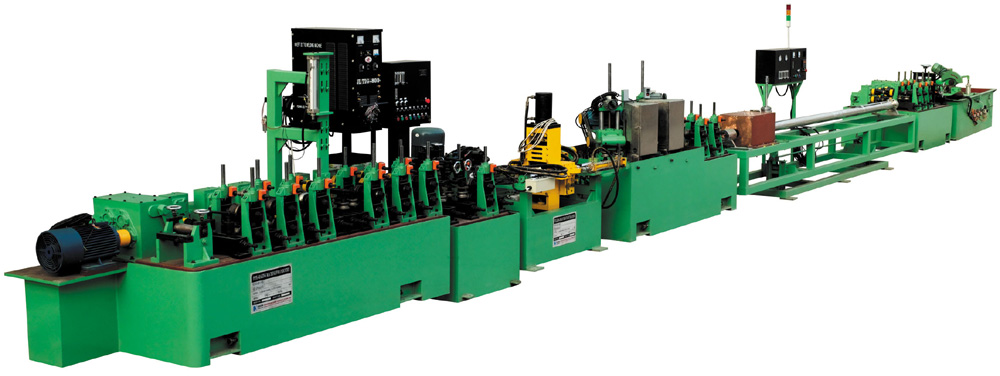

Industrial Pipe/Tube Making Machine

The machine is manufacturing industrial stainless steel pipes/tubes widely auto parts, auto exhaust, paper, petrol, medical use, refrigeration, chemical, food and beverage handling equipment, heating elements/heat exchanger...Etc.

Structures:

●Single side/double side uncoiler

●Strip butt welding equipment: manual welding table or shear and butt welding machine

●3-stage roller tube making machine

Forming section

Welding section

Sizing section

●Cooling section

●Weld bead grinder

Equipment for inside weld bead control (Optional )

In-line bright annealing equipment (Optional)

●Auto-cut off

●Run out table

●Electric control system

●TIG welding machine + cooling equipment/ Plasma welding machine + cooling equipment

●Unloading shelf

●Rolls made of Cr12MoV/SKD-11

Automatic production line:

uncoiling, forming, welding, grinding, inside weld bead removing, outside weld bead grinding, sizing, bright annealing, straightening, testing, letter spraying, fixing length, cutting, collecting. It can be done at one time.

Advantages:

a. Our machines are manufactured from finest materials. Steady, durable and long lifetime.

b. Automatic control, safe and easy to operate.

c. Easy to replace the molds, save working hour and increase efficiency.

d. Low noise.

e. The machine and make different type of stainless steel pipe/tube which are round, square, rectangle type of pipe/tube

Specifications:

Model |

horizontal axis diameter (mm) | vertical axis diameter (mm) | Pipe diameter (mm) |

Wall thickness (mm) | Main motor power | Machine size (L * W * H) (mm) |

| HD-G40 | 40 | 25 | Ф8-Ф51 | 0.5-2.0 | Front 7.5 KW Rear 5.5KW |

29.0 * 1.5 * 2.2 |

| HD-G50 | 50 | 30 | Ф25-Ф63 | 0.5-3.0 | Front 11KW Rear 7.5KW |

32.0 * 1.5 * 2.2 |

| HD-G60 | 60 | 40 | Ф50-Ф114 | 0.6-3.5 | Front 15 KW Rear 15KW |

35.0 * 1.8 * 2.2 |

| HD-G80 | 80 | 50 | Ф89-Ф168 | 1.0-4.5 | Front 18.5 KW Rear 18.5 KW |

40.0 * 2.5 * 2.2 |

| HD-G100 | 100 | 60 | Ф114-Ф219 | 1.0-5.0 | Front 22 KW Rear 22KW |

43.0 * 3.0 * 2.2 |

- Product Categories

- Coil Slitting Machine & CTL

- Stainless Steel Tube/Pipe Making Machine

- Stainless Steel Tube/Pipe Polishing Machine

- Metal Tube/Pipe Bending Machine

- Metal Tube/Pipe Cutting Machine

- Rotary Swaging Machine and Tube Tapering Machine

- Cold Roll Forming Machine

- Stainless Steel Sheet Polishing Machine

- Stainless Steel Round Pipe Internal Surface Polishing Machine

- Other Machinery

- More >>

- Contact Us

- Foshan Hengda Machinery Co., Ltd

- Tel: +86 757 8663 8695

- Fax: +86 757 8663 8696

- Emai: sales@fshdmachinery.com

- Msn: carolyang1028@hotmail.com

- Website: www.fshdmachinery.com

- More >>

2006-2013 © CopyrightFoshan Hengda Machinery Co., Ltd.All Rights Reserved

Plasma Welder

Plasma Welder TIG Welder

TIG Welder High Precision Pipe/Tube Making Machine

High Precision Pipe/Tube Making Machine Roller Sets

Roller Sets