Slitter Line

Slitting Machine is mainly used to slit kinds of wide steel strip into certain width and then recoil them to meet the request of various procedure for welded pipe and cold rolled section steel production. It can slit various metal materials, ferrous and non-ferrous metals such as cold or hot rolled carbon steel, stainless steel, aluminum, brass, copper, galvanized and different kind of special alloys can be slit by these lines.

Function:

A slitting line can do uncoiling, slitting and recoiling works. It usually works not only for the steel cutting industry, but more commonly for the pipe making industry. A lot of pipe production lines, longitudinal or spiral weld pipe line, start with a slitting line to produce coils with requested width. Our slitting lines, with delicate and advanced design, can fit various sizes of steel coils and can be easily adjusted to cut coils into needed width.

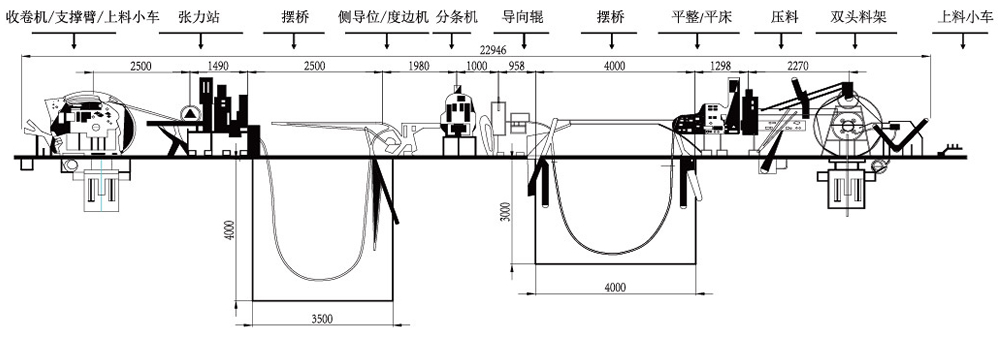

Process flow

Feed – uncoiling – pinching and leveling – rotary shear – scrap reeling – loop – tensioning – coiling - unloading

Structure:

● Coil Loading car

● Uncoiling machine

● Leveling machine

● Hydraulic shear

● Rotary shear

● Scrap winder

● Loop accumulator

● Tension stand

● Recoiler

● Coil stripper car

● Hydraulic system

● Electric system

● Related Accessories

Technique Specifications:

|

Model |

HD-S450 |

HD-S650 |

HD-S850 |

HD-S1050 |

HD-S1400 |

HD-S1600 |

|

Strip width(mm) |

100-420 |

150-620 |

150-820 |

300-960 |

400-1250 |

600-1550 |

|

Material Thickness(mm) |

0.25-1.5 |

0.25-2.0 |

0.3-2.0 |

0.3-2.0 |

0.3-3.0 |

0.3-3.0 |

|

Slit Strands |

3-10 |

3-15 |

3-15 |

3-20 |

3-20 |

3-20 |

|

Capacity(kw) |

50 |

80 |

90 |

110 |

250 |

380 |

|

Slitting Speed (m/min) |

0-100 |

0-120 |

0-120 |

0-150 |

0-150 |

0-150 |

|

Coil Weight (ton) |

3 |

6 |

8 |

10 |

10-20 |

15-32 |

|

Size(L*W)(m) |

13*4 |

15*4 |

15*4 |

15*5 |

18*7 |

20*8 |

Note: Slitting line can be designed and made according to special demands, above mentioned data are for reference only.

Features

● By means of Programmable Logic Controller (PLC), system performance is based upon the characteristics of various metal sheets, and switch high / low speed operating mode automatically , so as to achieve improved efficiency and reduced maintenance dramatically.

● For lower malfunctioning, the material uncoiler uses an expand / shrink hydraulic cylinder that is mounted on an integrated steel frame .

● The material uncoiler is equipped with a high efficiency disc type brake, its tension is adjusted by the air pressure loop.

● Under this circumstance, the time for tension adjustment is reduce, also, the forced monetary braking is occurred thus free from loosen of coil .

● The pre - loader is equipped with DC Various - Speed motor drive, so that a synchronized speed cooperate to the production line could be governed .

● Slitting knives are mounted on integrated frame with a separated 1 transmission, that means enhanced rigidity structure of Machine, lower vibration amplitude of knives, and excellent yields could be produced.

● The datum plane and accuracy of sitting Knives' axes are all to be fabricated within 0.006mm in tolerance, so that makes higher duration of slitting knives and much excellent , accuracy of outputs of the slitting line.

● For securing the stability of slitting line during operation, the tension controlled roll - up device with slip differential structure is designed for the waster.

● The tension pad uses high elastics and resistive carpet as surface materials, so keep the outputs of the Line smoother. In addition, it also equipped a pressure-balance device to keep an even-pressure over the both side of materials that toched with the tightener.

● The recoiler is equipped with an improved / high rigid holder, that causes reduce of lead time . An hydraulic pressure adjustable back - pressure device is equipped on the separator mechanism , so that a constant hold - pressure could be reached for recoil.

● Self - tension design enable to retain a better tightness during recoil.

CAD

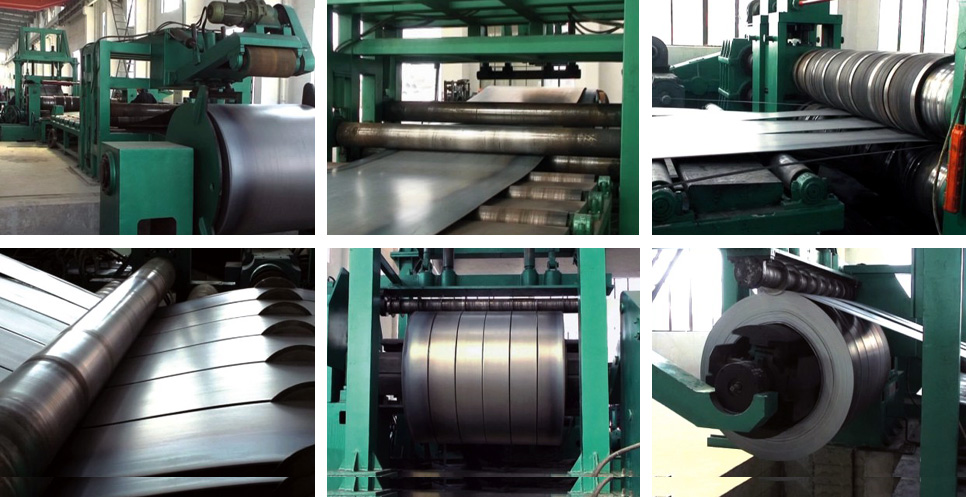

Slitting machine detailed pictures

- Product Categories

- Coil Slitting Machine & CTL

- Stainless Steel Tube/Pipe Making Machine

- Stainless Steel Tube/Pipe Polishing Machine

- Metal Tube/Pipe Bending Machine

- Metal Tube/Pipe Cutting Machine

- Rotary Swaging Machine and Tube Tapering Machine

- Cold Roll Forming Machine

- Stainless Steel Sheet Polishing Machine

- Stainless Steel Round Pipe Internal Surface Polishing Machine

- Other Machinery

- More >>

- Contact Us

- Foshan Hengda Machinery Co., Ltd

- Tel: +86 757 8663 8695

- Fax: +86 757 8663 8696

- Emai: sales@fshdmachinery.com

- Msn: carolyang1028@hotmail.com

- Website: www.fshdmachinery.com

- More >>

2006-2013 © CopyrightFoshan Hengda Machinery Co., Ltd.All Rights Reserved

Coil Turning Machine

Coil Turning Machine Flying Shearing CTL Line

Flying Shearing CTL Line Cut To Length Line

Cut To Length Line Fittings

Fittings