CNC Oil Pressure Hydraulic Servo Bending Machine

The machine is CNC control, transfer tube feeding 2-axis servo control, pipe hydraulic servo control economic model for the CNC. Suitable industries: Automobile, motorcycle accessories, furniture, emblem of the equipment, medical equipment, etc.

Machine Features:

● With the latest dialog touch screen monitor, all programming and machine’s function or messages are displayed alternative in bilingual languages( English/Chinese)

● Sketches of the machine’s top-view are displayed, touch the relative graphic square knob to run the function of machine

● Various mode/configuration setting with in automatic or manual situation. Such as with/without mandrel, booster, mandrel lubrication, etc. Also running machine step by step or continuous, etc.

● Programmed self-diagnostic and warning alarm function to display all malfunction or error messages, and indicate trouble shooting. Also recorded the recent messages for maintenance reference.

● By touch screen easy to use, simple to set up program and quick tools changing minimizes machine-setting time.

● Can set compensation parameter for tube/pipe bending rebounding back

● Can set each axis speed in order to save working time and increases production efficiency

● Counter function for bend working piece

● Anticipated mandrel ret raction unit (optional) for to make sure the surface of curve section more smooth and prefect

● Booster device easily bends tube at large size or very tight radius and keer very ideal curve ovality

● Maximum memory storage is 500 sets

● Per memory’s sets is programmed with 20 bending data

● Multiple protection devices assure of operator safety

● Can be manually operated or semi-automatic, and fully automatic

● By automatic sensing and error indicating, avoid machine or tools damaged cause by misused.

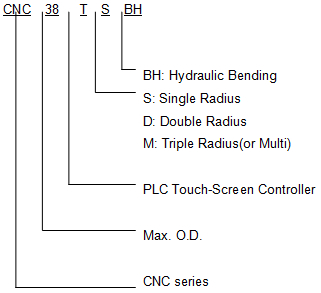

How we name our CNC Hydraulic servo bending machine?

Specifications:

| Model | CNC38 TSBH / TDBH |

CNC50 TSBH / TDBH |

CNC65 TSBH / TDBH | CNC80 TSBH / TDBH |

|||||

| Max. Pipe Diameter(mm) | Ф38× 2.0 | Ф50.8× 2.0 | Ф65× 3.0 | Ф80× 2.5 | |||||

| Range of center line Radius(mm) | 30-170 | 30-220 | 40-280 | 50-300 | |||||

| Max. Bending Radius Difference (mm) | \ | 50 | \ | 65 | \ | 75 | \ | 85 | |

| Max. Bending Angle(°) | 190° | 190° | 190° | 190° | |||||

| Max. Effective Distance of Manderl (mm) | 2200 | 2200 | 2500 | 3000 | |||||

|

Speed |

Feeding Speed (mm/sec) | 1350 | 1350 | 1300 | 910 | ||||

| Rotating Speed(B)(°/sec) | 300 | 300 | 270 | 240 | |||||

| Bending Speed(C)(°/sec) | 100 | 80 | 65 | 75 | |||||

|

Reproducibility |

Feeding(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||

| Rotating (°/sec) |

±0.1 | ±0.1 | ±0.1 | ±0.1 | |||||

| Bending (°/sec) |

±0.15 | ±0.15 | ±0.15 | ±0.15 | |||||

| Hydraulic Motor(Kw) | 5.5 | 7.5 | 11 | 11 | |||||

| Total Power(Kw) | 7 | 9.5 | 13.5 | 14.5 | |||||

| Max. Hydraulic pressure(Kg/cm2) | 140 | 140 | 140 | 140 | |||||

| Oil Tank Capacity(L) | 130 | 145 | 180 | 200 | |||||

| Working Height (mm) | 1100 | 1100 | 1100 | 1100 | 1225 | 1225 | 1200 | 1200 | |

| Machine Size ( L*W*H)(mm) |

4200*900*1300 | 4850*1000*1400 | 4850*1500*1600 | 6500*1380*1500 | |||||

| Machine Weight (Kgs) | 2200 | 3100 | 3500 | 6000 | |||||

Related Products

- Product Categories

- Coil Slitting Machine & CTL

- Stainless Steel Tube/Pipe Making Machine

- Stainless Steel Tube/Pipe Polishing Machine

- Metal Tube/Pipe Bending Machine

- Metal Tube/Pipe Cutting Machine

- Rotary Swaging Machine and Tube Tapering Machine

- Cold Roll Forming Machine

- Stainless Steel Sheet Polishing Machine

- Stainless Steel Round Pipe Internal Surface Polishing Machine

- Other Machinery

- More >>

- Contact Us

- Foshan Hengda Machinery Co., Ltd

- Tel: +86 757 8663 8695

- Fax: +86 757 8663 8696

- Emai: sales@fshdmachinery.com

- Msn: carolyang1028@hotmail.com

- Website: www.fshdmachinery.com

- More >>

2006-2013 © CopyrightFoshan Hengda Machinery Co., Ltd.All Rights Reserved

CNC Servo Bending Machine

CNC Servo Bending Machine Double-Head Hydraulic Pipe Bending Machine

Double-Head Hydraulic Pipe Bending Machine Single-Head Hydraulic Pipe Bending Machine

Single-Head Hydraulic Pipe Bending Machine CNC Oil Pressure Hydraulic Servo Bending Machine

CNC Oil Pressure Hydraulic Servo Bending Machine