CNC Servo Bending Machine

The machine is with graphic guidance display, friendly using and easy operation. Its simulation of preset bending program allows you to see the graphs prior to production. Bending feasibility examining on paper through the work cycle to discover possible abnormal conditions or interference before actual production.

Smaller size CNC bending machine suitable industries: Brake & Fuel piping, Air Conditioner Piping, Heating Element, etc.

Bigger size CNC bending machine suitable industries: Aircraft, Architecture, Furniture, Auto Exhaust Pipes, Car Frame, Car Seat, Handle Bar, Exercise Equipment, etc.

Machine Features:

● Industrial touch screen LCD color monitor

● Use pc based control system not PLC controller

● Large program date can be stored on computer hard drive on limitations on sets of program or number of bends per program

● Fully selectable operational modes in Manual semi-automatic and full automatic cycles

● Programmable in up to 10 different speeds independently for each axis

● An automatic parts counter is installed to assist with production control

● May view 3D visual parts display on screen immediately after inputting YBC(LRA) data

● YBC data entry automatically calculates the actual required tube length and enters it into the part program.

● 3D graphics simulation of preset bending system

● Bending feasibility examining simulation through the work cycle.(option)

● Compensation of tube spring back and stretch

● Computer modem dial up link with factory service center for software upgrades and operational assistance

● Step operation in the manual mode allows the set up people to read error messages and make part data or procedural changes in the program reducing set up scrap and prevening machine/part interference

● Hydraulic oil is continuously filtered and co0led during machine operation

● Part data is stored in hard memory and not lost during machine down time or power failure

● Programmable hitch feeding allows for bending of extremely long parts when no mandrel is used

● Programmable pressure die forward motion and return during the beading cycle allows are of shorter pressure die when bending larger radii

● Individual or simultaneous machine motion is programmable for any bend or for the complete part as needed

● System error messages are pinpointed on monitor minimizing or correction down time for correction down time

● The system computer continually performs data diagnostic checks to detect errors in part data input

● User friendly on screen icons are easy selected by touch limiting potential errors

● Messages on the monitor can be displayed in Chinese/English or other languages

● Individual bending data and sequence can be stored separately.

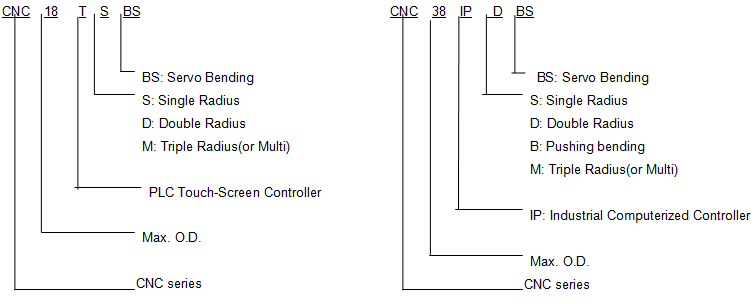

How we name our CNC servo bending machine?

Specifications:

| Model | CNC18TSBS/ TDBS |

CNC25 TSBS/ TDBS |

CNC38 IPSBS/ IPDBS |

CNC38 IPBBS/ IPMBS |

CNC50 IPSBS/ IPDBS |

CNC50 IPBBS/ IPMBS |

CNC65 IPSBS/ IPDBS |

CNC80 IPSBS/ IPDBS | |||||||||

| Max. Pipe Diameter(mm) | Ф18× 1.6 | Ф25.4×1.8 | Ф38× 1.8 | Ф38× 1.8 | Ф50× 2.0 | Ф50× 2.0 | Ф65× 2.0 | Ф80× 2.5 | |||||||||

| Range of center line Radius(mm) | 10-80 | 10-100 | 25-160 | 25-160 | 30-250 | 30-250 | 40-260 | 50-280 | |||||||||

| Max. Bending Radius Difference (mm) | \ | 30 | \ | 40 | \ | 50 | 50 | 50 | \ | 65 | 65 | 65 | \ | 75 | \ | 85 | |

| Max. Bending Angle(°) | 190° | 190° | 190° | 190° | 190° | 190° | 190° | 190° | |||||||||

| Max. Effective Distance of Manderl (mm) | 1200 | 1200 | 2200 | 2750 | 2200 | 3200 | 2500 | 3000 | |||||||||

|

Speed |

Feeding Speed (mm/sec) | 2000 | 2200 | 1350 | 1350 | 1350 | 750 | 1350 | 910 | ||||||||

| Rotating Speed(B)(°/sec) | 320 | 320 | 300 | 300 | 270 | 270 | 270 | 240 | |||||||||

| Bending Speed(C)(°/sec) | 226 | 226 | 170 | 170 | 105 | 108 | 100 | 75 | |||||||||

|

Reproducibility |

Feeding(mm) | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ||||||||

| Rotating (°/sec) |

±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||||||||

| Bending (°/sec) |

±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | ±0.1 | |||||||||

| Hydraulic Motor(Kw) | 1.7 | 2 | 2.2 | 2.2 | 3.8 | 3.8 | 7.5 | 7.5 | |||||||||

| Total Power(Kw) | 4 | 5 | 8.5 | 12.5 | 14 | 18 | 22 | 27 | |||||||||

| Max. Hydraulic pressure (Kg/cm2) | 35 | 35 | 140 | 140 | 140 | 140 | 140 | 140 | |||||||||

| Oil Tank Capacity(L) | 80 | 80 | 130 | 130 | 145 | 145 | 160 | 180 | |||||||||

| Working Height (mm) | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1225 | 1225 | 1200 | 1200 | |

| Machine Size ( L*W*H)(mm) |

2850*800*1200 | 2850*800*1200 | 4100*1050*1500 | 4800*1100*1400 | 4300*1050*1560 | 5300*1050*1560 | 5600*1150*1500 | 6500*1450*1750 | |||||||||

| Machine Weight (Kgs) | 900 | 950 | 2300 | 2750 | 3100 | 3680 | 4000 | 6000 | |||||||||

Related Products

- Product Categories

- Coil Slitting Machine & CTL

- Stainless Steel Tube/Pipe Making Machine

- Stainless Steel Tube/Pipe Polishing Machine

- Metal Tube/Pipe Bending Machine

- Metal Tube/Pipe Cutting Machine

- Rotary Swaging Machine and Tube Tapering Machine

- Cold Roll Forming Machine

- Stainless Steel Sheet Polishing Machine

- Stainless Steel Round Pipe Internal Surface Polishing Machine

- Other Machinery

- More >>

- Contact Us

- Foshan Hengda Machinery Co., Ltd

- Tel: +86 757 8663 8695

- Fax: +86 757 8663 8696

- Emai: sales@fshdmachinery.com

- Msn: carolyang1028@hotmail.com

- Website: www.fshdmachinery.com

- More >>

2006-2013 © CopyrightFoshan Hengda Machinery Co., Ltd.All Rights Reserved

Double-Head Hydraulic Pipe Bending Machine

Double-Head Hydraulic Pipe Bending Machine Single-Head Hydraulic Pipe Bending Machine

Single-Head Hydraulic Pipe Bending Machine CNC Oil Pressure Hydraulic Servo Bending Machine

CNC Oil Pressure Hydraulic Servo Bending Machine CNC Servo Bending Machine

CNC Servo Bending Machine