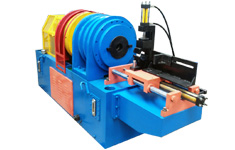

Manual Tube Tapering Machine Specifications

Stainless steel tube/pipe tapering machine, also known as tube/pipe end forming machine, is mainly used for tapering stainless steel pipe, iron pipe, aluminum pipe and so on. By applying foreign advanced technology, the tube tapering machine can process diameter of tube range from ∮12-∮76mm, pipe thickness from 0.5-3mm. With good processing quality, lower cost and high efficiency, the tube tapering machine is an ideal choice for clients to process various kinds of tubes.

Applications:

widely used in light & lamp industry, metal furniture, auto parts, motorcycle, bicycle, air-conditioning, exercise equipment, sanitary ware, building decoration, security doors and windows, guardrails, staircase, steel furnishment and iron industries, etc.

Features:

1. The machine is for tapering round pipe/tube end, manual or semi-Automatic model machinery are available for your choosing.

2. Pipe/Tube Material:iron, steel, stainless steel, aluminum,copper etc.

3. Processed workpiece surface is quite smooth, without scar

4. Easy operation, easy to change different pattern moulds.

5. Very Low noise during working, 75-85db.

6. Stable and reliable performance, high productivity.

7. Molds can be customized, as we make molds as well ,the molds will match the machine perfectly.

Manual Tube Tapering Machine Specifications:

| Model | HD-MФ38*300 | HD-MФ50*400 |

| pipe range (mm), | ∮ 12 - ∮ 38 | ∮ 16 - ∮ 51 |

| wall thickness (mm) | 0.5-2.0 | 0.7-3.0 |

| Max. forming length (mm) | 300 | 400 |

| forming times(S / times) | 10 | 10 |

| main motor (KW) | 3 | 4 |

| spindle speed (rev / min) | 300 | 200 |

| spindle height(mm) | 800 | 800 |

| Machine size(m) | 1.0*0.95*1.3M | 1.1*1.1*1.3M |

| total weight (kg) | ≈ 1000 | ≈ 1200 |

Related Products

- Product Categories

- Coil Slitting Machine & CTL

- Stainless Steel Tube/Pipe Making Machine

- Stainless Steel Tube/Pipe Polishing Machine

- Metal Tube/Pipe Bending Machine

- Metal Tube/Pipe Cutting Machine

- Rotary Swaging Machine and Tube Tapering Machine

- Cold Roll Forming Machine

- Stainless Steel Sheet Polishing Machine

- Stainless Steel Round Pipe Internal Surface Polishing Machine

- Other Machinery

- More >>

- Contact Us

- Foshan Hengda Machinery Co., Ltd

- Tel: +86 757 8663 8695

- Fax: +86 757 8663 8696

- Emai: sales@fshdmachinery.com

- Msn: carolyang1028@hotmail.com

- Website: www.fshdmachinery.com

- More >>

2006-2013 © CopyrightFoshan Hengda Machinery Co., Ltd.All Rights Reserved

Semi-Automatic Square Tube Tapering Machine

Semi-Automatic Square Tube Tapering Machine Manual Tube Tapering Machine Specifications

Manual Tube Tapering Machine Specifications Semi-Automatic Tube Tapering Machine Specifications

Semi-Automatic Tube Tapering Machine Specifications Semi-Automatic Rotary Swaging Machine

Semi-Automatic Rotary Swaging Machine